Unbranded See Description

| Brand | Unbranded 2014 |

| Model | See Description |

| Released Year | 2014 |

| Type | Printers |

| Series | 3D Systems ProJet |

| Printing Technology | Multi-Jet Printing (MJP) |

| Status | Discontinued |

Quick view

Overview

The 3D Systems ProJet series comprises professional-grade 3D printers designed for rapid prototyping and manufacturing. Utilizing advanced multi-jet printing (MJP) technology, these printers enable high-resolution, detailed outputs with smooth surface finishes. They support a variety of photopolymer materials, allowing for diverse applications including casting patterns, concept modeling, and functional prototypes. The printing process involves jetting layers of photopolymer material which are then cured with UV light, providing accuracy up to finer microns. The systems include integrated build platforms with automatic calibration features for enhanced precision. Connectivity is facilitated through USB and Ethernet interfaces, supporting seamless integration within office environments.

Specifications

| Type | Thermal shipping labels |

| Product Line | 3D Systems ProJet |

| Technology | Dot Matrix |

| Output Type | Black & White |

| Connectivity | USB 2.0, Ethernet 10/100Base-T |

| Input Type | Color |

| Features | Copier |

| Model | See Description |

| Supported Paper Size | A0 (841 x 1189 mm) |

| Maximum Resolution | 180 x 180 DPI |

| Black Print Speed | 1 ppm |

| Memory | 1 MB |

| Country/Region of Manufacture | Afghanistan |

| Manufacturer Warranty | 1 Month |

| Scanning Resolution | 200x200 DPI |

| Supported Scanning Sizes | A0 (841 x 1189 mm) |

| Grayscale Depth | 8 Bit |

| Image Sensor | CCD |

| Color Depth | 8 Bit |

| MPN | B0CFY3YQP8 |

| UPC | Does not apply |

| Printing Technology | Multi-Jet Printing (MJP) |

| Layer Resolution | 16 - 32 microns |

| Build Volume | Up to 11 x 6.5 x 8 inches (280 x 165 x 203 mm) depending on model |

| Material Compatibility | Photopolymer plastics, castable wax resins |

| Print Speed | Up to 30 mm/hour |

| Supported File Formats | STL, 3DS |

| Operating System Compatibility | Windows 7 and later |

| Software | 3D Sprint software for print management |

| Dimensions | Approximately 26 x 22 x 20 inches (660 x 560 x 510 mm) |

| Weight | Approx. 80 kg (varies by model) |

| Power Requirements | 110-240V AC, 50/60 Hz |

| Color Capabilities | Monochrome and limited color options depending on the model |

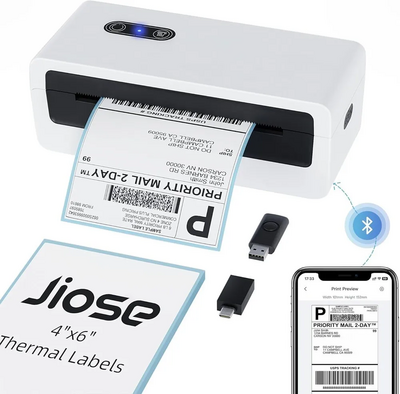

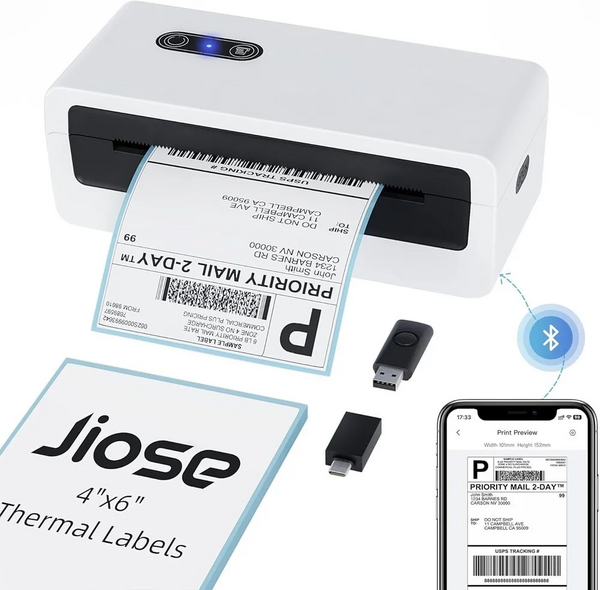

Images

Key Advantages

The 3D Systems ProJet series offers exceptional print resolution achieving layers as fine as 16 microns, resulting in highly detailed parts. Its wide material compatibility enables diverse functional applications, from durable plastics to castable wax. User-friendly software provides intuitive control over print settings and job management, increasing workflow efficiency. The printers are designed with a sealed build chamber to minimize post-processing and ensure consistency. Modular components and easy-to-replace cartridges reduce downtime and maintenance efforts. Additionally, these systems are designed for relatively quiet operation suitable for office environments.

Limitations

The ProJet series, while precise, typically involves higher operational costs due to specialized photopolymer materials. Print build volumes are limited in size compared to larger industrial 3D printers, restricting large-part fabrication. The photopolymer resins require careful storage and handling to avoid degradation. Post-processing such as support removal and cleaning can be labor-intensive for complex models. The learning curve for optimal print outcomes may be steep for new users unfamiliar with Multi-Jet Printing technology. Software updates and compatibility issues may arise with older systems given the product's age and discontinued nature.

FAQ

What printing technology do 3D Systems ProJet series printers use?

The 3D Systems ProJet series uses Multi-Jet Printing (MJP) technology, which jets layers of photopolymer material and cures them with UV light for precise, high-resolution prints.

Are the ProJet printers suitable for office environments?

Yes, they are designed to operate quietly with sealed build chambers and efficient workflows, making them suitable for office and professional settings.

What materials are compatible with the ProJet printers?

ProJet printers support a variety of photopolymer materials including durable plastics and castable wax resins for diverse application needs.

Can the ProJet series print large parts?

The build volume is limited relative to industrial 3D printers, so it is best suited for small to medium-sized parts.

Is specialized training required to operate these printers?

Yes, some familiarity with 3D printing and Multi-Jet Printing technology is recommended to achieve optimal print quality.

What connectivity options are available?

ProJet printers typically support USB and Ethernet connections for easy integration into networked office environments.

Are replacement parts and accessories still available?

Since the series is discontinued, obtaining genuine replacement parts may be challenging and require sourcing from third-party vendors.

Disclaimer

The content on is provided for general informational purposes only. We do not guarantee the accuracy, completeness, or reliability of any information, specifications, or visuals presented on the site.

is not responsible for any content, images, or data uploaded or shared by users. Users are solely responsible for the content they submit.

We may include links to third-party websites for convenience. We do not endorse or take responsibility for the content or policies of any external sites.

Use of the site is at your own risk. Always verify critical information independently before making decisions based on content from this website.