Unbranded Printer

| Brand | Unbranded 2010 |

| Model | Printer |

| Released Year | 2010 |

| Type | Printers |

| Series | 3D Systems ProJet |

| Status | Active |

Quick view

Overview

The 3D Systems ProJet is a professional-grade 3D printer designed for office electronics applications, primarily in prototyping and rapid manufacturing. It uses proprietary additive manufacturing technology to create high-resolution 3D models layer by layer. The printer supports multiple materials, including resin and composite powders, enabling diverse functional and aesthetic prototyping. Advanced laser or inkjet print heads enable precise deposition and curing of materials, ensuring detailed output with smooth surface finishes. Integration with standard CAD software allows straightforward design-to-print workflows. The device features a controlled build environment to maintain consistency and reduce warping.

Specifications

| Supported Paper Size |

|

| Model | Printer |

| Maximum Resolution |

|

| Black Print Speed |

|

| Product Line |

|

| Connectivity | USB 2.0, Ethernet |

| Type |

|

| Memory |

|

| Technology |

|

| MPN | Does Not Apply |

| UPC |

|

| Print Technology | Binder Jetting / UV Resin Curing |

| Build Volume | Up to 30 x 24 x 20 cm (varies by model) |

| Layer Resolution | 16 to 32 microns |

| Material Types | Photopolymer resins, composite powders |

| Software Compatibility | Standard CAD (STL, OBJ, etc.) |

| Power Requirements | 110-240V AC, 50/60 Hz |

| Printer Dimensions | 590 x 600 x 940 mm |

| Weight | Approx. 70-80 kg |

| Operating Temperature | 18-27°C |

| Supported Operating Systems | Windows XP and above |

| Color Printing | Available on select models |

| Post-Processing | Requires cleaning and curing station |

| Custom Bundle | No |

| Material | Plastic |

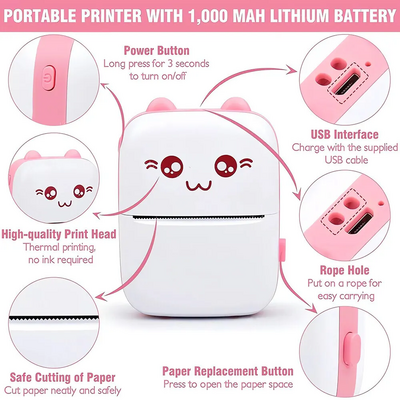

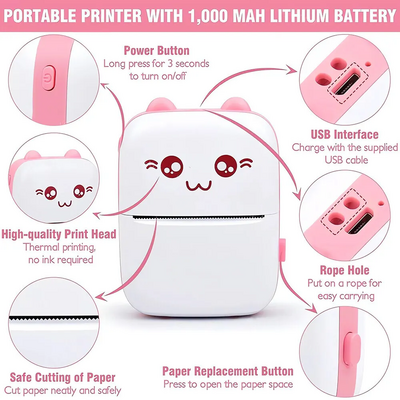

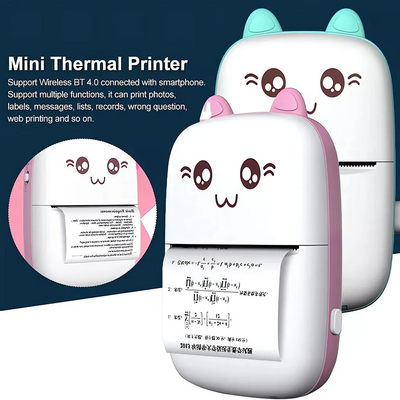

| Suitable for | be used to print learning materials for wrong questions |

| Design | Easy to use and carry |

| Function | print problem-solving drawings and photos on the web |

| Output Type | Black & White |

| Features | Portable |

| Color | PinkWhite, GreenWhite, FullBlue |

| Input Type | Color |

Images

Key Advantages

The 3D Systems ProJet offers high-resolution printing capable of producing detailed parts with smooth surface finish. It supports a variety of materials, enhancing versatility for different prototyping needs. The device is relatively compact and suitable for office environments without requiring specialized facilities. User-friendly interfaces and integration with common CAD applications simplify workflow processes. Rapid build times improve efficiency for iterative design and testing. Additionally, the machine provides reliable repeatability for small-batch production and functional prototypes.

Limitations

The ProJet series 3D printer can be limited by its build volume, which may not accommodate larger parts. Operating costs can be relatively high due to proprietary materials and maintenance requirements. The device requires skilled operators to optimize print settings and troubleshoot complex prints. Some material options may have mechanical properties not suitable for end-use parts under stress. Post-processing time can add to the overall production cycle depending on material and finish needs. Additionally, the technology might lag behind newer 3D printers in speed and multi-material capabilities.

FAQ

What printing technology does the 3D Systems ProJet use?

The 3D Systems ProJet typically uses binder jetting or UV-curable resin technology depending on the model, enabling precise additive manufacturing layer by layer.

Which materials are compatible with the ProJet 3D printer?

It supports a range of materials such as photopolymers, composite powders, and resins designed for prototyping and functional part creation.

What is the maximum build volume of the ProJet printer?

The build volume varies by specific ProJet model but generally fits small to medium-sized parts appropriate for office and prototyping use.

Is the 3D Systems ProJet suitable for end-use manufacturing?

While excellent for prototyping and concept models, some ProJet materials may not possess the durability required for demanding end-use applications.

Can the printer integrate with common CAD software?

Yes, it supports standard CAD file formats allowing users to export designs seamlessly for printing.

What maintenance does the ProJet printer require?

Regular cleaning of print heads, material refill, and calibration are necessary to maintain print quality and reliability.

Is the 3D Systems ProJet still in production?

The ProJet model series continues to be supported though some older versions might have been succeeded by newer models.

Disclaimer

The content on is provided for general informational purposes only. We do not guarantee the accuracy, completeness, or reliability of any information, specifications, or visuals presented on the site.

is not responsible for any content, images, or data uploaded or shared by users. Users are solely responsible for the content they submit.

We may include links to third-party websites for convenience. We do not endorse or take responsibility for the content or policies of any external sites.

Use of the site is at your own risk. Always verify critical information independently before making decisions based on content from this website.