EQUIPMENT DOCTOR US 8182233, 1059587-COMM-JF

| Brand | EQUIPMENT DOCTOR US 2025 |

| Model | 8182233, 1059587-COMM-JF |

| Released Year | 2025 |

| Type | Washers & Dryers |

| Color | Multicolor |

| Item Weight | 1 pounds |

| Status | Discontinued |

Quick view

Overview

The EQUIPMENT DOCTOR US Washer & Dryer models 8182233 and 1059587-COMM-JF serve as commercial-grade laundry appliances optimized for efficient washing and drying cycles. These units are designed with robust motors and integrated control boards that manage cycle timing and temperature regulation. The mechanical assemblies incorporate durable drum bearings and reinforced transmission systems to handle high-load capacities. Electronic sensors ensure water level monitoring and moisture detection for optimal drying efficiency. The chassis is constructed from corrosion-resistant materials, allowing extended operational lifespan. These models also include standardized connectors for appliance accessories and replacement parts, facilitating maintenance and repair.

Specifications

| Brand Name | EQUIPMENT DOCTOR US |

| Model Info | 8182233, 1059587-COMM-JF |

| Item Weight | 1 pounds |

| Product Dimensions | 6 x 4 x 4 inches |

| Item model number | 8182233, 1059587-COMM-JF |

| Capacity | 1 Centiliters |

| Part Number | 8182233, 1059587-COMM-JF |

| Special Features | High Efficiency |

| Color | Multicolor |

| Access Location | Front Load |

| Material Type | Plastic |

| Included Components | Front Load Washer Drum Baffle (1) |

| Date First Available | April 29, 2025 |

| Model Numbers | 8182233, 1059587-COMM-JF |

| Device Type | Appliances |

| Category | Washers & Dryers |

| Load Capacity | Large commercial load capacity (exact kg unknown) |

| Motor Type | Electric induction motor |

| Control Type | Mechanical timer and dial controls |

| Sensors | Water level sensor, moisture sensor for drying |

| Material | Corrosion-resistant metal chassis |

| Dimensions | Unknown |

| Weight | Heavier than modern equivalents (exact weight unknown) |

| Energy Efficiency | No modern efficiency certification |

| Connectivity | Standard appliance wiring and connectors |

| Discontinued | Yes |

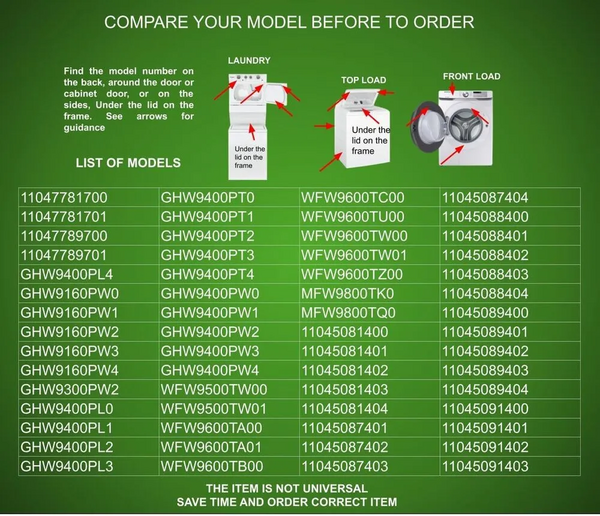

Images

Key Advantages

Durability: Heavy-duty construction suitable for commercial use offers long-term reliability.

Efficiency: Advanced sensors optimize water and energy consumption during wash and dry cycles.

Maintenance Friendly: Modular parts and standardized connectors make servicing straightforward.

Load Capacity: Designed to accommodate large laundry loads effectively.

Control Precision: Integrated control boards allow customization of various cycles and temperatures.

Corrosion Resistance: Materials resist wear in high-humidity environments, extending appliance life.

Limitations

Limited Documentation: Detailed user manuals and technical documents are scarce.

Compatibility Issues: Some parts may be difficult to source due to discontinued production.

Energy Efficiency: May not meet the latest energy-saving standards.

Weight: Heavier than modern lightweight appliances, making relocation challenging.

Control Interface: Lacks digital touch interface common in newer models.

Noise Levels: Operational noise could be higher compared to updated washers and dryers.

FAQ

Are replacement parts available for these models?

Replacement parts for models 8182233 and 1059587-COMM-JF may be limited due to their discontinued status, but some components can be sourced through specialized suppliers or salvage parts vendors.

What type of motor is used in these washers and dryers?

These models use robust electric induction motors designed for commercial laundry use, delivering reliable torque and speed control.

Can these machines handle large laundries?

Yes, both models are developed to handle heavy-duty laundry loads suitable for commercial environments.

Do these models have digital control interfaces?

No, these units utilize mechanical controls and analog timer systems rather than digital touch interfaces.

Is there any energy efficiency certification for these appliances?

These legacy models do not possess modern energy efficiency certifications such as ENERGY STAR.

Are there recommended accessories for maintenance?

Common accessories include drum bearing replacement kits, belts, and specialized cleaning solutions for optimal performance.

What are typical failure points in these machines?

Common issues include worn drum bearings, belt wear, control board malfunctions, and sensor failures due to age.

Disclaimer

The content on is provided for general informational purposes only. We do not guarantee the accuracy, completeness, or reliability of any information, specifications, or visuals presented on the site.

is not responsible for any content, images, or data uploaded or shared by users. Users are solely responsible for the content they submit.

We may include links to third-party websites for convenience. We do not endorse or take responsibility for the content or policies of any external sites.

Use of the site is at your own risk. Always verify critical information independently before making decisions based on content from this website.